- HOME

- MARKETS

- Additive manufacturing

- Aerospace

- Automotive

- Ceramics

- Cold spray

- Cosmetic

- General industry

- Air Atomized Aluminum Powder - General Industry

- Air atomized Aluminum Powder - High Purity

- Aluminum Pigments - Leafing Roof Coating

- Aluminum Pigments - Solvent Based

- Aluminum Pigments - Water Based

- Powder Coating flakes

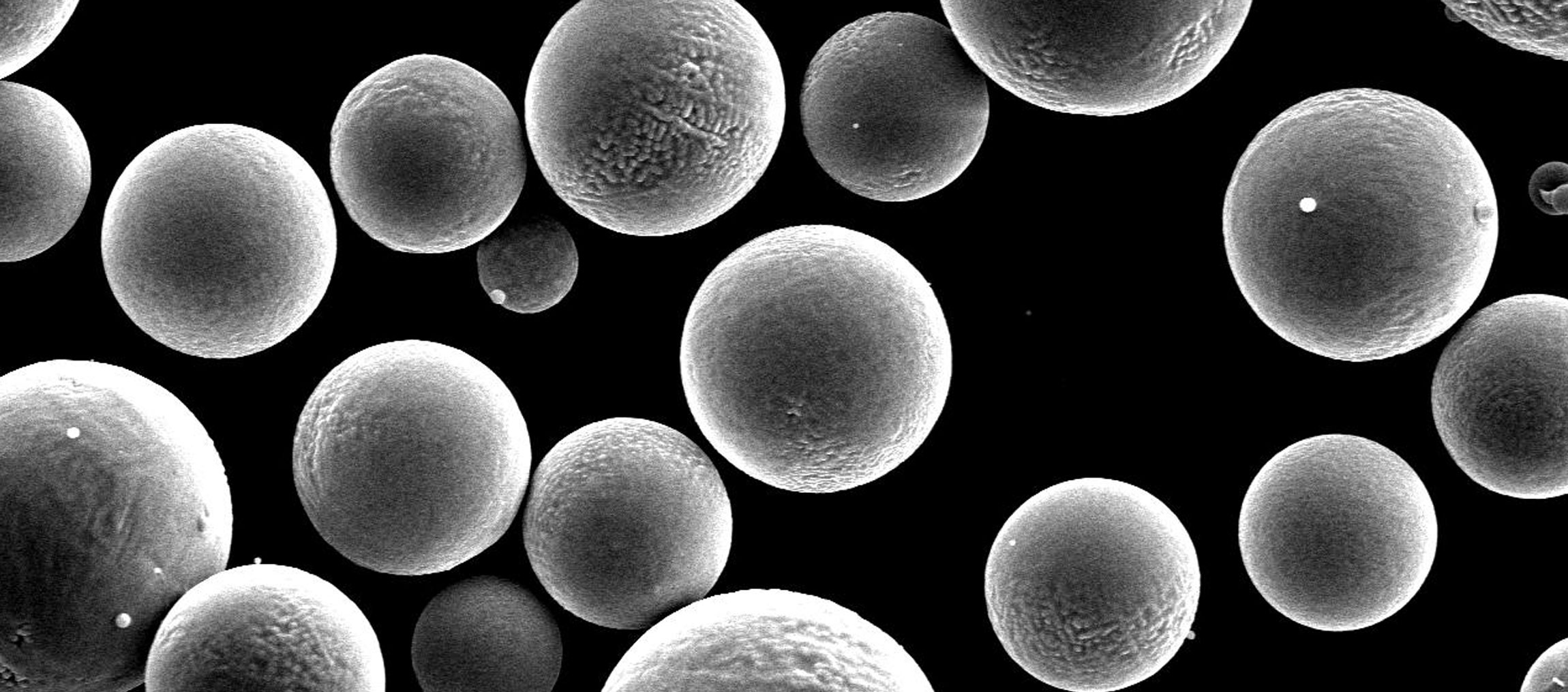

- Spherical Aluminum Powder - General Industry

- Spherical Aluminum Powder - High Purity

- Defense

- Thermal Management

- Security and Anti-Counterfeit

- PRODUCTS

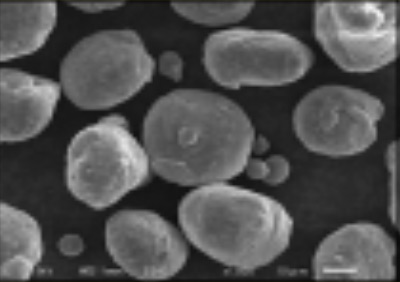

- Air Atomized Aluminum Powder - General Industry

- Air Atomized Aluminum Powder - High Purity

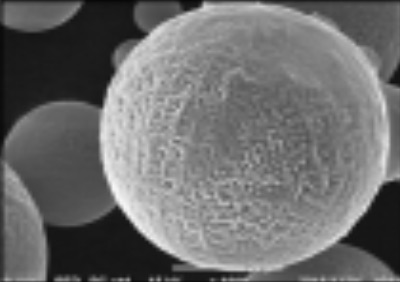

- Aluminum Alloy Powders

- Aluminum Nitride - Granulated Form

- Aluminum Nitride Powders - Filler Applications

- Aluminum Nitride Powders - Sintering Applications

- Aluminum Pigments - Leafing Roof Coating

- Aluminum Pigments - Solvent Based

- Aluminum Pigments - Water Based

- CHROMASHINE® - Interference Aluminum Pigments

- Cosmicolor® Celeste

- Cosmicolor® Flourish

- Cosmicolor® Luminous

- Cosmicolor® Metallics

- Cosmicolor® Stratone

- Friend Color® - Colored Aluminum Pigments

- Hyperchroma® Aluminum Pigments

- METASHINE® Glass Flakes

- Powder Coating flakes

- Scalmalloy®

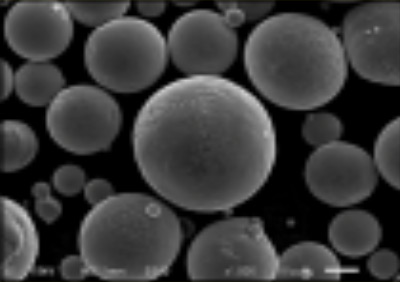

- Spherical Aluminum Powder - Aerospace

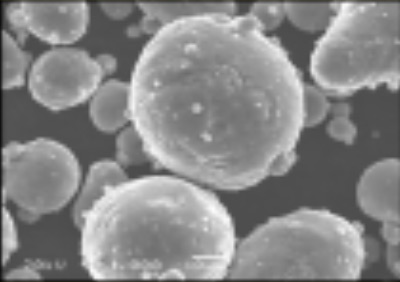

- Spherical Aluminum Powder - General Industry

- Spherical Aluminum Powder - High Purity

- Spherical Aluminum Powder - Thermal Management

- Vacuum Metalized Aluminum Pigments

- ONLINE INFORMATION

- JOBS

- CONTACT